Active Ingredient Production |Purification Process | Reaction Monitoring

Online measurement methods enable reliable reaction tracking in real time

The analysis of substance mixtures using spectroscopic measurement methods is widely used in applications in the chemical and pharmaceutical industries, among others. The main advantages are the quantitative and qualitative determination of a defined substance or parameter with high precision and reproducibility and therefore optimum process control and process reliability. Conventional methods, such as gas chromotagraphy (GC), are problematic for some types of process where precise reaction endpoint determination is crucial, primarily due to the time delay in the measurement results. This is the case with purification processes, for example.

In order to meet the strict purity requirements of the chemical, food and pharmaceutical industries, an additional purification step is often carried out during the manufacturing process. A common purification process is the washing out of impurities from a system by adding a washing solution.

The detectability of an impurity in the production of an organic compound is to be confirmed by the presence of a precisely defined amount of this impurity in the washing solvent at the end of the washing process. The impurity to be removed cannot be detected by spectroscopic methods but only by gas chromatography. This presents a challenge for online process monitoring, especially for process measurements that require continuous analysis or very fast analysis times. In such cases, a chromatographic separation method represents a technical limitation.

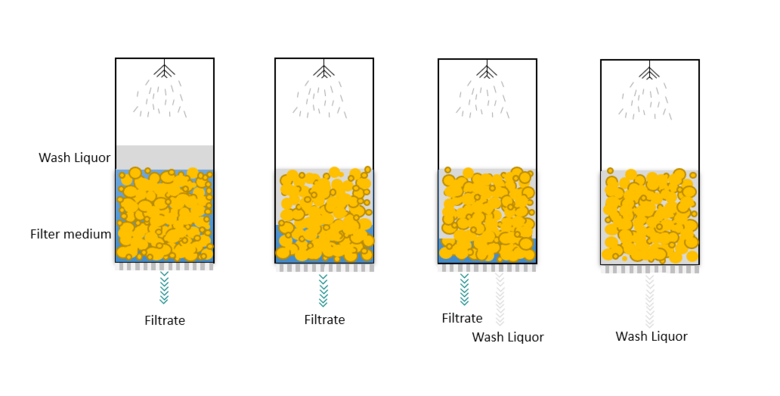

During a purification process, it is necessary to extract a contaminant from the filter cake that forms during the washing process. The washing solvent after the reactor is monitored and the washing process is to be interrupted if it falls below a predefined threshold value.

Schematic representation of a filter cake wash

A more detailed description on how this application was realized using online measurement technology can be found in our detailed application report, which you can download from the info column at the top of the page.